Pre-Season Spreader Prep Checklist

Summer! A time for parties, pools, barbeques… and preparing your salt spreader for winter use. Having functional equipment when the snow starts to finally fall calls for attentive preparation well before the start of the autumn season.

From Smith Metal Works’ shop foreman, Chuck Raes: a Pre-Season Salt Spreader checklist to help keep you on track and prepared for the winter weather to come.

1. Check All Electrical

Connections

- Inspect wiring for damage – both truck side and spreader

side; replace or repair as necessary. - Look for corrosion on components. Clean with corrosion

inhibiting spray or di-electric grease to ensure good

connection.

2. Inspect Spreader for Damage

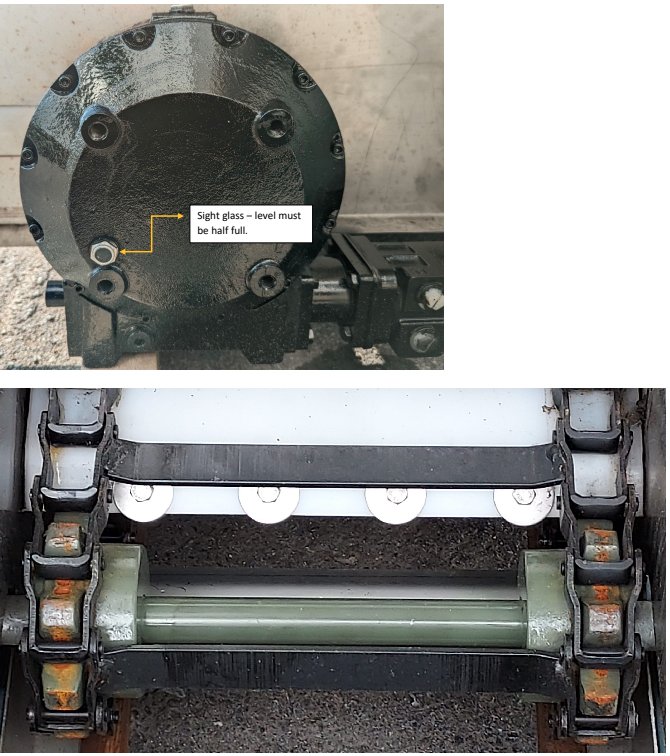

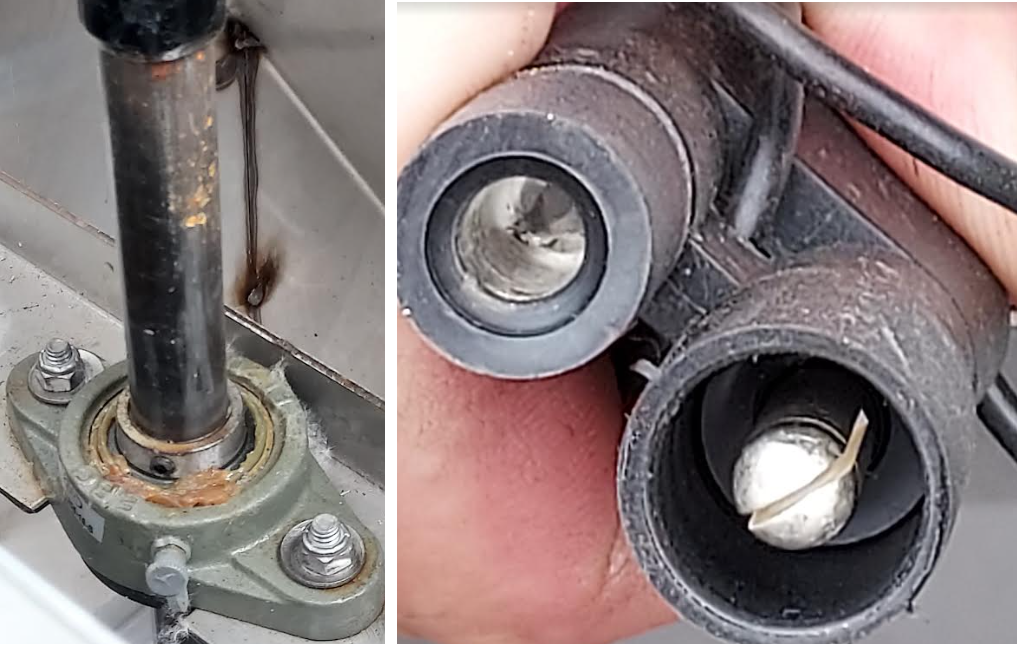

- Look for bent shafts, blown bearings, rusty chains, or a

seized motor.

3. Before You Test Run The

Spreader

- Have a can of chain lube or used motor oil handy. Spray the

chains before you run the spreader. Safety first! - Grease the spreader bearings, using a low viscosity moly

grease.

4. Running The Spreader

- Watch your amperage. High amp draw indicates problems.

- Don’t be stingy with applying chain lube. Rusty, crusty chains

will cause your spreader to “over-work.” - Listen to your spreader. Unusual groans, moans, squeals and

squeaks tell you something needs attention. - Look and listen for vibrations. If your spreader is shaking

excessively, the spinner shaft is probably bent or the

bearings need attention.

Remember: An ounce of prevention…

is worth a pound of Cure!

Thank you for owning a Smith product, we wish you luck and a happy salting season. Questions, requests or concerns? Please contact us here, or use this form to submit a specific spreader part request.